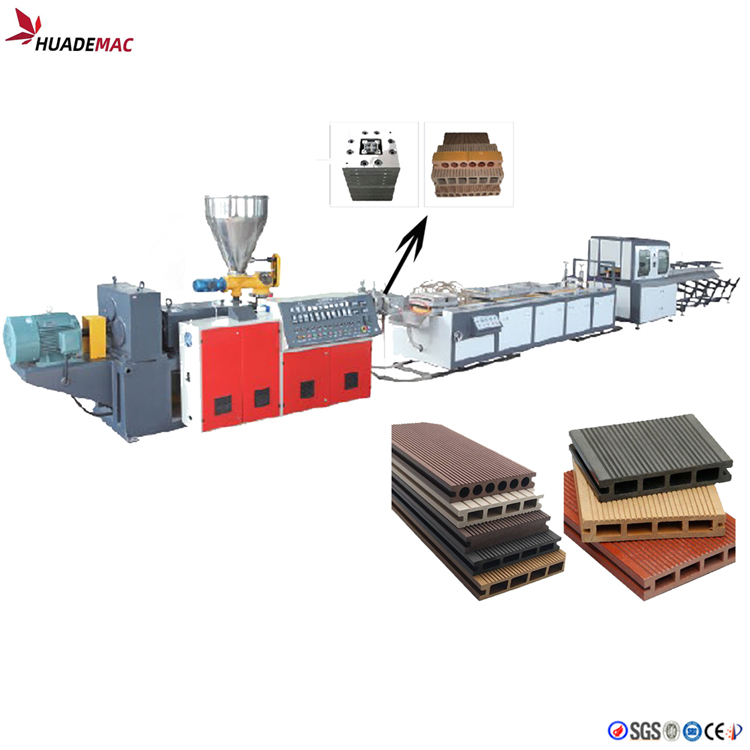

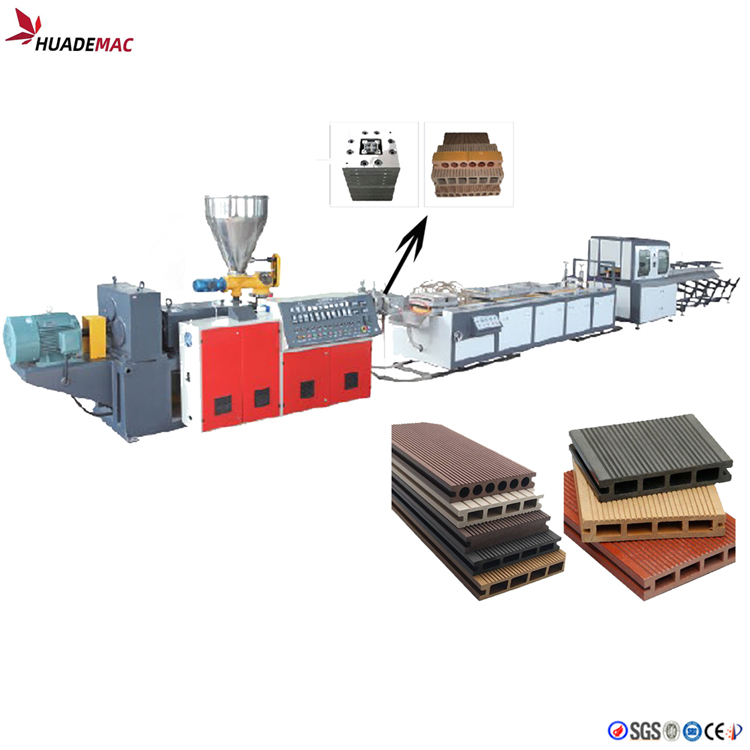

Conical twin screw for WPC extrusion High automatic running Easy operation with less maintenance

- Any Questions?[email protected]

- Get in Tough+86-13601562675

Conical twin screw for WPC extrusion High automatic running Easy operation with less maintenance

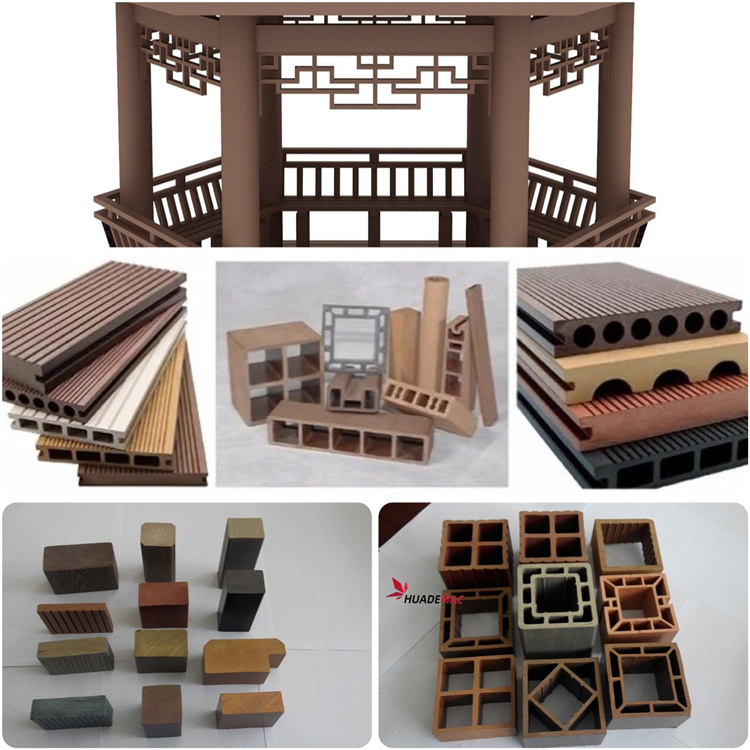

Wide Range of Applications

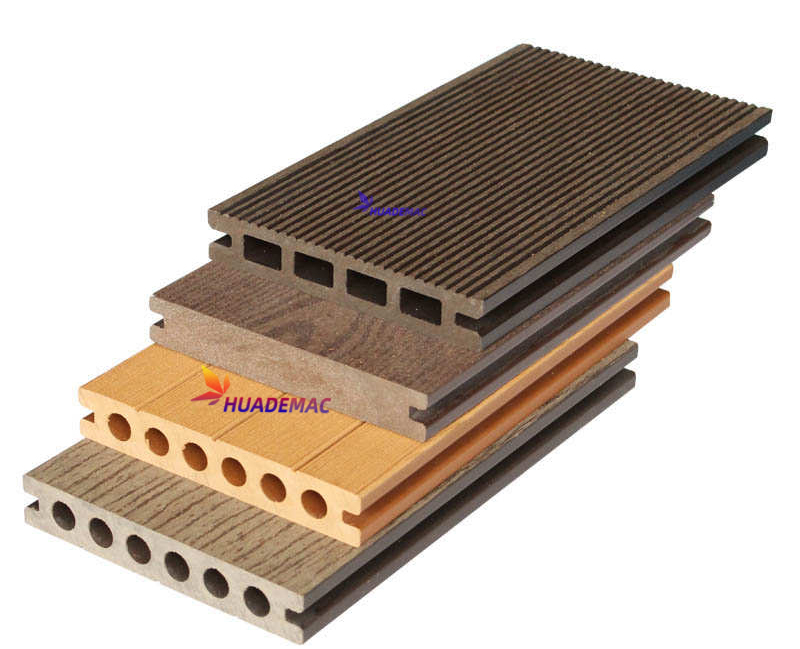

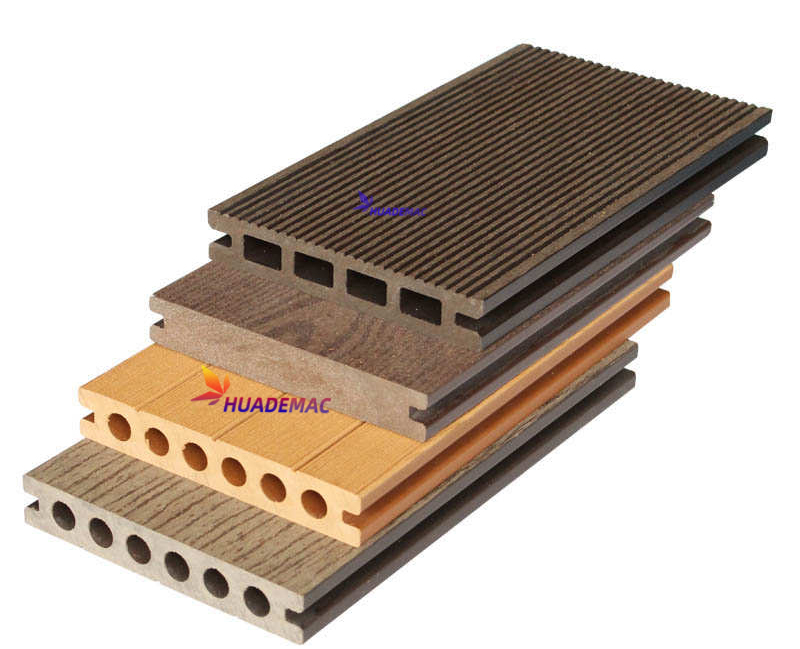

Wood plastic composites can successfully replace pure natural products thanks to their longer life and other beneficial properties. Such as decking and fencing elements, roofing ,trellises and door-frame profiles, picnic tables, benches .landscape timber, patios,gazebos and walkways, playground equipment.

Main Features Of Extrusion Line:

l Extruder adopts WPCd dedeciated screw, make sure best plastisizing effect, furhter make sure best final product shape

l Extruder speed and haul off speed controlled by ABB frequency inverter, saving power and easy adjusting speed

l Extruder temperature adopt PID control, temperature fluctuation self adjusting, it realise the high automatic level

l Equipped with infrared tracking device which can elimintate the problem of fluctuation of extrusion flow rate, further can make sure get best product

l Lower power consumption, it can save 25-30% electrical power consumption comparing with most same kind PVC ceiling extruder.

l Economical price, suitable for large scale investment.

Product Width(mm) | 200 | 240 | 300 | 600 | 900 | 1200 |

Extruder | SJZ55/110M | SJZ65/132M | SJZ80/156M | SJZ92/188M | ||

Motor Power(kw) | 22 | 37 | 55 | 110 | ||

Vacuum Pump(kw) | 4X1 | 5.5X1 | 5.5X1 | 5.5X2 | 5.5X1 7.5X1 | 5.5X1 7.5X1 |

Water Pump (kw) | 2.2 | 2.2 | 4 | 5.5 | 7.5 | 7.5 |

Capacity(kg/h) | 70 | 100 | 110 | 180 | 300 | 400 |