Outstanding,uniform product quality Cost-effective and flexible production Compact and space saving

- Any Questions?[email protected]

- Get in Tough+86-13601562675

Outstanding,uniform product quality Cost-effective and flexible production Compact and space saving

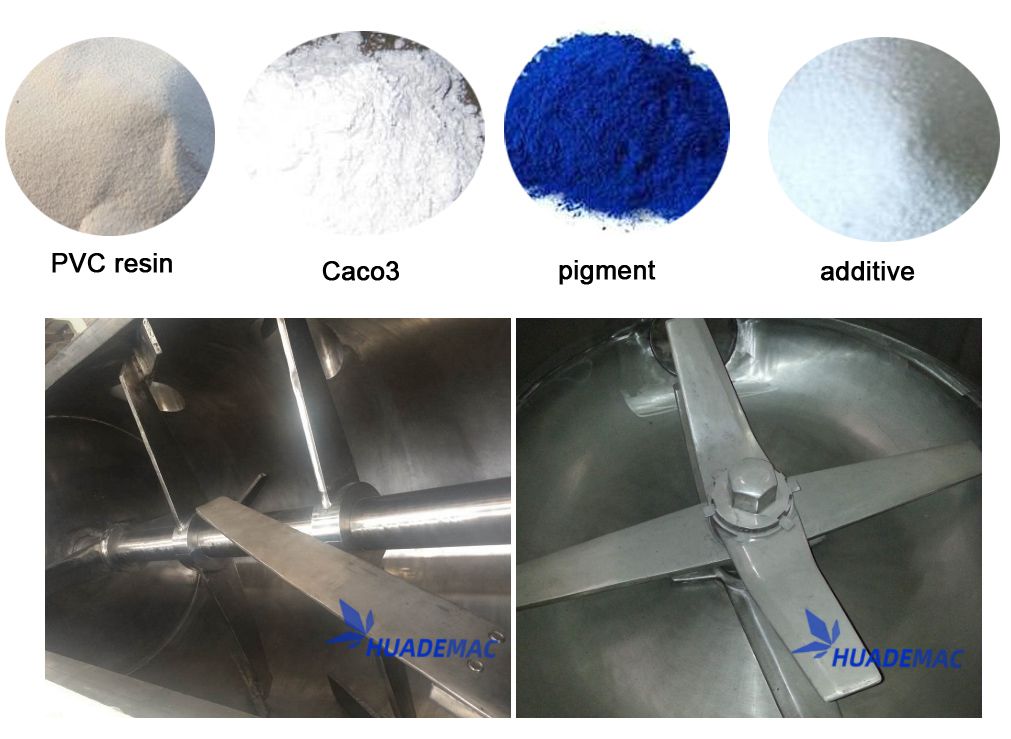

This machine is used for mixing, stirring, drying and coloring of various materials in plastics, rubber, daily chemical industry and other industries.

This unit is introduced and digested and absorbed advanced foreign technology. All electrical appliances imported famous brand electrical appliances, and can be programmed PLC computer control.

The utility model has the advantages of high automation degree and high mixing speed, and the blades are precision stainless steel pressure casting.

In particular, the blades of the cooling machine adopt the advanced spiral mixing structure of foreign countries, it is difficult to have dead angle.

The utility model has the advantages of fast cooling speed, clean discharge and mixed effect.

Features & Advantages

The inside wall of pot body of heating mixer is made of δ 6mm SUS304 stainless steel. The inside surface of pot body is smooth, hard and raw material is not easy to adhere. Also it offers characteristics such as high wear resistance, high corrode resistance, and high temperature resistance.

The lid is made of ZL102 cast aluminum, and is polished. The lid is light and easy to open.

The bottom of mixer are made of δ 8mm SUS304 stainless steel. The agitating blade is made of ZG1Cr18Ni9Ti stainless steel and polished.

The lid is opened by pneumatic equipment. The material of mixer is cooled through water circulation. The main shaft of heating mixer runs depending on deep groove ball bearing, which is reliable and stable.

The seal of main shaft adopts frame oil seal of different specifications and sizes. The main shaft of heating mixer is equipped with air seal.

The motor and gear box connected by belt, which ensure reliable work and avoid of overload.

SRL-W | Heat/Cool | Heat/Cool | Heat/Cool | Heat/Cool | Heat/Cool |

Total volume(L) | 300/1000 | 500/1500 | 800/2500 | 1000/3000 | 800*2/4000 |

Useful volume(L) | 225/700 | 330/1000 | 600/1500 | 700/2100 | 1200/2700 |

Stirring speed(rpm) | 475/950/80 | 430/860/70 | 370/740/60 | 300/600/50 | 350/700/65 |

Mixing time(min) | 8-12 | 8-15 | 8-15 | 8-15 | 8-15 |

Power(KW) | 40/55/7.5 | 55/75/15 | 83/110/22 | 110/160/30 | 83/110*2/30 |

Weight (kg) | 3300 | 4200 | 5500 | 6500 | 8000 |

Huade manufacture the PVC mixers in a variety of sizes with customizable parts, perfectly tailored to our clients' needs. Integral to the blending system, our high speed PVC mixing systems allow for high productivity with PVC compounding, mixing and more.