Highly productivity Constant high output Easy to operate Outstanding,uniform product quality Cost-effective and flexible production High automation Compact and space saving

- Any Questions?[email protected]

- Get in Tough+86-13601562675

Highly productivity Constant high output Easy to operate Outstanding,uniform product quality Cost-effective and flexible production High automation Compact and space saving

Twice The Throughput With Dual-Strand Extrusion

Higher extruder performance will increase your profit margins as long as other costs are carefully controlled.

The initial capital investment for a modern high-performance extruder line is higher, but space requirements and labour costs are unaltered.

Pipe throughput is often constrained by the die pressure, the calibration system or the haul-off speed.

Double strand extrusion doubles the extruder's throughput of small-diameter pipe.

Adjusting the haul-off speed and the cutter function separately for each strand cuts material consumption to an all-time low, because differences in material flow can be allowed for and wall-thickness kept within tight tolerances.

Pipe Range | 16-40mm | 20-63mm | 75-160mm |

Extruder | SJZ51/105 | SJZ65/132 | SJZ80/156 |

Power | 18.5kw | 37kw | 110kw |

Capacity | 120kg/h | 250kg/h | 450kg/h |

Line Speed | 12m/min | 10m/min | 6m/min |

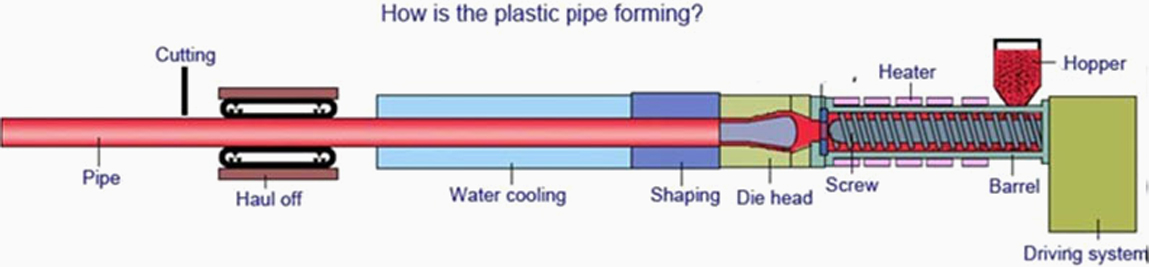

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. With the development of economy, more and more plastics are used in people's daily life. Consequently, a large quantity of plastic extruder, plastic extrusion line, plastic extrusion machine are used to process PP, LLDPE, LDPE, HDPE, PVC, ABS, etc. in pipe extrusion, profile extrusion, filament extrusion, film extrusion, sheet extrusion and pelletizing.

We have focused on plastic machinery over 21 years with rich experience and strong technology. Top quality and the turn-key service including installation, test running and training workers in your local factory. We are your trustworthy partner !