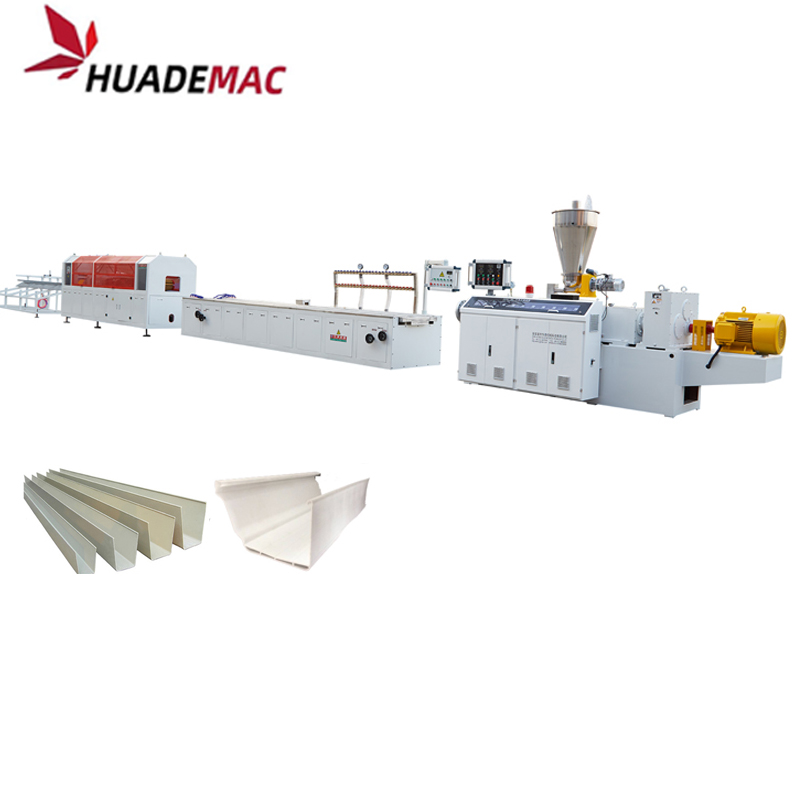

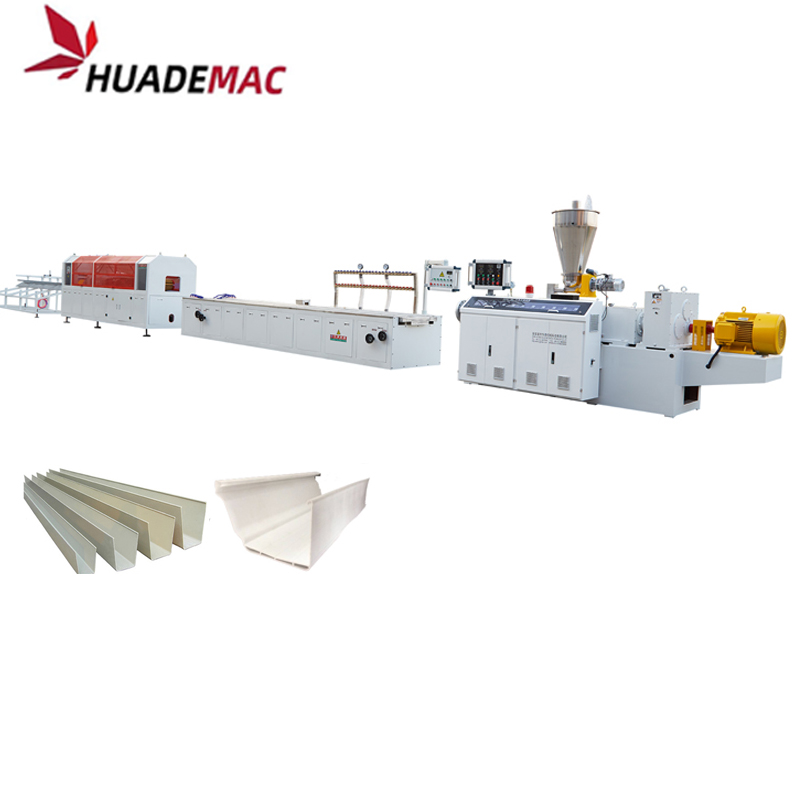

Outstanding,uniform product quality Cost-effective and flexible production Compact and space saving

- Any Questions?[email protected]

- Get in Tough+86-13601562675

Outstanding,uniform product quality Cost-effective and flexible production Compact and space saving

The typical layout for a PVC rain guttermanufacture includes the following modules:

Conical twin screw extruder

Calibration table

Caterpillar haul-off

Cutting units

Tilting table

Auxiliary equipments

Conical Twin Screw Extruder

The SJSZ-series extruder is designed for the PVC profile application.

We target to provide the optimal solutions for the customer’s special needs with the advantage of flexibility in material choices, high performance and long durability.

High flexibility in raw material combinations

Gentle and homogeneous plastifcation

Barrel with air cooling system

AC motors for low energy consumption

Control panel can be optional with PID temperature instrument or PLC touch screen

Die Head

Materials: 40Cr Steel

Single cavity design

Calibration Table

Motor-driven height and side movement

Motor-driven longitudinal movement

Manuel tilting movement

All parts that are in contact with water is made of stainless steel

Low maintenance cost

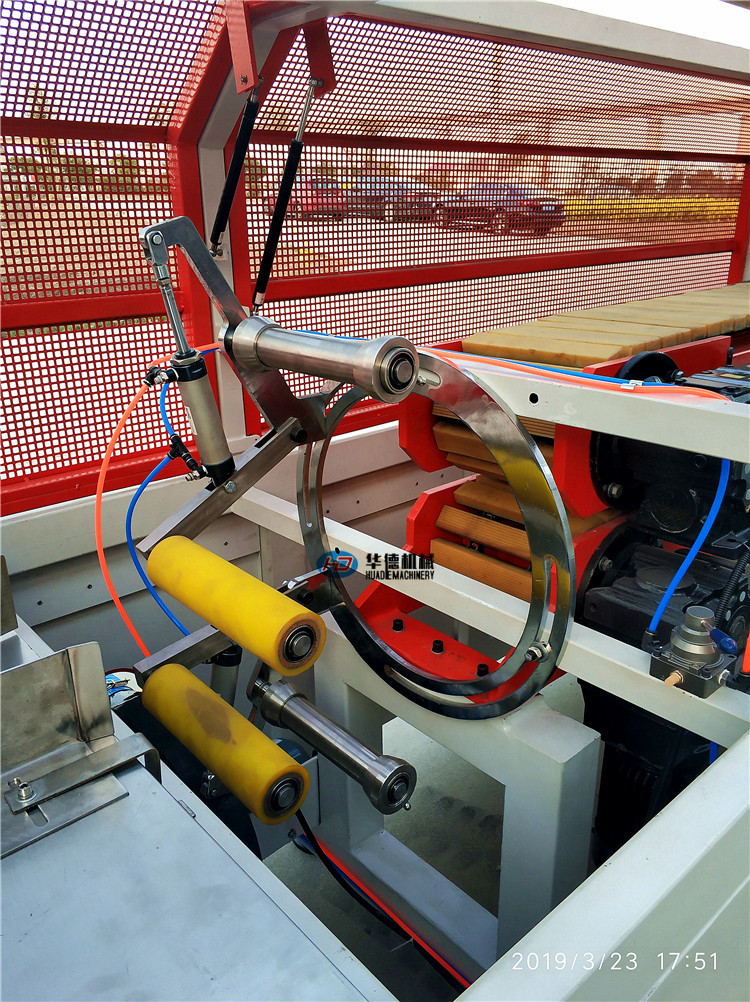

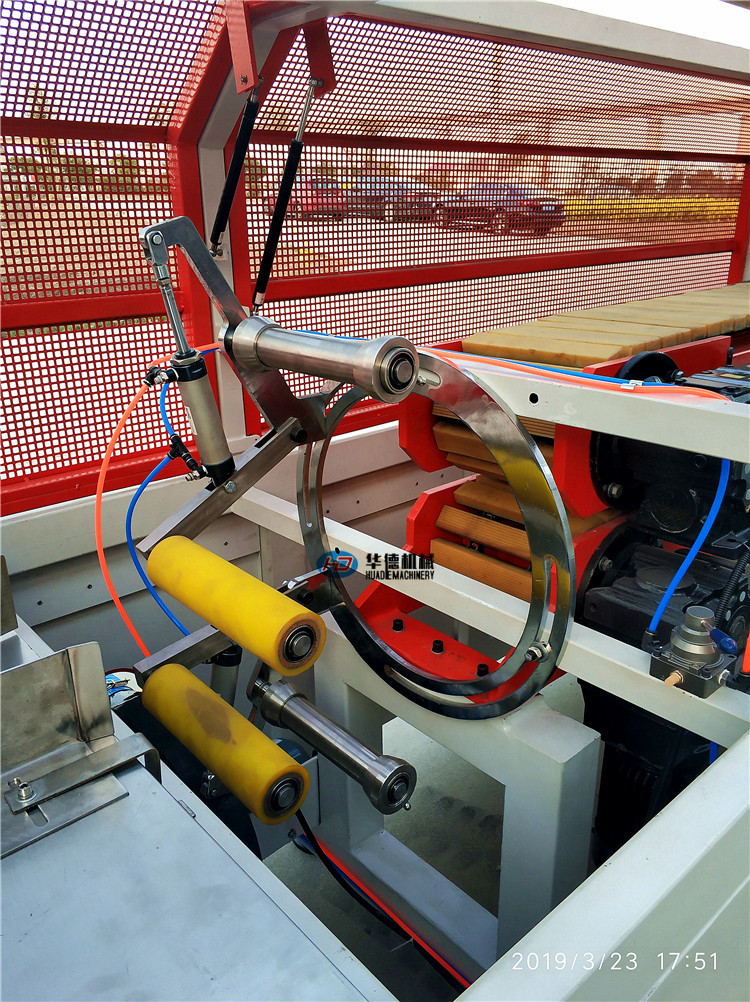

Caterpillar Haul-Off

Synchronous control

Upper and lower caterpillar is driven separately by the frequency inverter

Frequency Motor/servo motor driving

High friction fact and anti-wear out silicon rubber Pads

Metering counter device

Cutting Units

Universal or Cast Aluminium fixture unit

High Quality Alloy Blades

Smooth Cutting surface;

Tilting Table

Stainless steel 304 as touching material

Discharge driving by air cylinder

Extruder | SJSZ65/132 |

Main Motor Power | 37kw |

Capacity | 200-250Kg/h |

Space occupation | L.28MXW.4MxH.3M |

Control | PID |