Outstanding,uniform product quality Cost-effective and flexible production Compact and space saving

- Any Questions?[email protected]

- Get in Tough+86-13601562675

Outstanding,uniform product quality Cost-effective and flexible production Compact and space saving

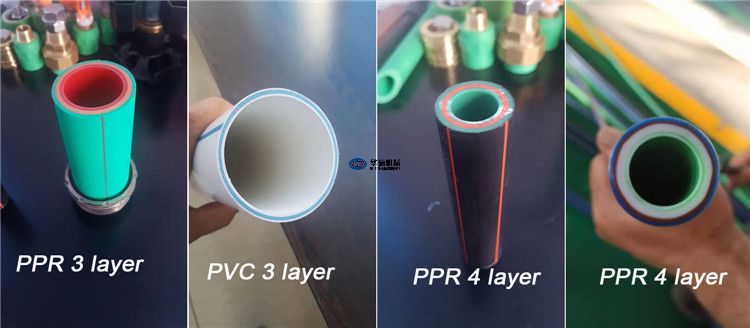

We offer complete turnkey production lines for PPR PPRC IPS pipe.

A wide range of single screw extruders in various sizes and capacities.

Our screw design is chosen based on our clients material combination to ensure a homogeneous mixture, better plastification and production efficiency. Our production lines come in a wide range of configurations capable of producing the pipes from 16mm up to 160mm.

Complete line Included

Single screw extruder machine

Vacuum & cooling tank

Haul off (puller) machine

Cutter machine

Accumulator machine

Coiler machine

Pipe diameter(mm) | 16 – 63 | 75-160 |

Extruder (inside and outside layer ) | 65/33 | 75/33 |

Main motor power(kw) | 45 | 90 |

Length of vacuum tank(mm) | 6000 | 9000 |

Length of cooling tank(mm) | 6000 | 6000 |

haul off (puller ) | 2 caterpillar | 3 caterpillar |

Max. Capacity (kg/h) | 150 | 250 |

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. With the development of economy, more and more plastics are used in people's daily life. Consequently, a large quantity of plastic extruder, plastic extrusion line, plastic extrusion machine are used to process PP, LLDPE, LDPE, HDPE, PVC, ABS, etc. in pipe extrusion, profile extrusion, filament extrusion, film extrusion, sheet extrusion and pelletizing.

We have focused on plastic machinery over 21 years with rich experience and strong technology .top quality and the turn-key service including installation , test running and training workers in your local factory . we are your trustworthy partner !