Manufacturer of pipe technology solutions

- Any Questions?[email protected]

- Get in Tough+86-13601562675

Did you know that one of the most versatile and durable types of pipes are made from PVC plastic? Industrialists have been using PVC pipes for 80 years. They have played a major role in servicing multiple applications in various industries all across the world.

If you compare the PVC pipes to metal pipes, they are much more resistant to corrosion and succumb to contraction and thermal expansion.

PVC pipe machinery and pipes come in various fittings and sizes. Depending on the PVC variants, you can use PVC pipe machinery for hot as well as cold applications.

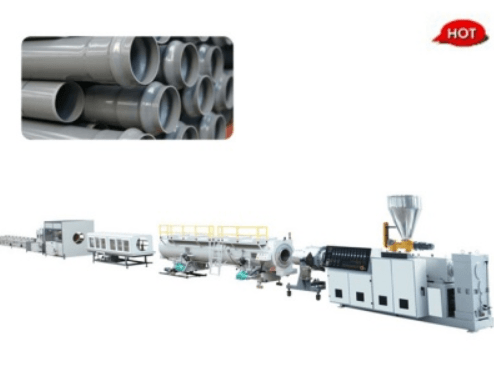

PVC pipe machinery is mainly particularly for PVC pipe manufacture with multitude wall thickness, diameter, and material. The PVC pipe extrusion line basically structured using a calibrated vacuum tank, twin-screw extruder in a conical shape, stacker, cutter, haul-off and etc.

The machinery that PVC pipe production line suppliers provide produces big and small PVC pipes in a large volume within a short time span.

PVC pipe machinery for sale usually includes a vacuumed spray tank, an extruder, a double pipe vacuum tank, a haul-off system or unit consisting of dual pipes, cutting unit, cooler, high-speed mixture mixer, die head and another die head with double pipes.

There are several applications for PVC pipe machinery. Some of them being:

• Municipal and civil drainage and water supply.

• Engineering for tap water piping.

Manu industrialists and manufacturers make huge investments on extrusion lines every day. The purpose of personal and business investment is universal, that is, to ensure that the product is paying back for itself.

Before making big decisions, it is important to invest properly. This is the only way that one can be sure about the extrusion line’s quick payback.

PVC pipe production line suppliers should have a clear policy and a logical approach with their customers. To gain a quick return on investment, efficiency of the product that the PVC pipe extrusion line suppliers provide has a prominent effect on it.

However, the return on investment id different on each product and changes accordingly throughout different market sectors. In some cases, chasing the optimum return on investment could take years. whereas, in some cases, it can be achieved in even a year.

The main point is, it largely depends on the efficiency and maintenance of PVC pipe machinery. Moreover, customized professional advice from the suppliers could also advantage you and enhance your return on investment rate.

There processors and manufacturers strive to reduce the expenses on the PVC pipe machinery so that they can boost the extrusion line productivity. They overlook many factors such as the screw design, shut-down procedure, start-up procedure, spillage, change-over, process control, line control and etc. Among all these, material cost is the largest factor affecting the return on investment. So, if a processor wants to have payback for the extrusion line, he must consider above-mentioned factors as well.