Manufacturer of pipe technology solutions

- Any Questions?[email protected]

- Get in Tough+86-13601562675

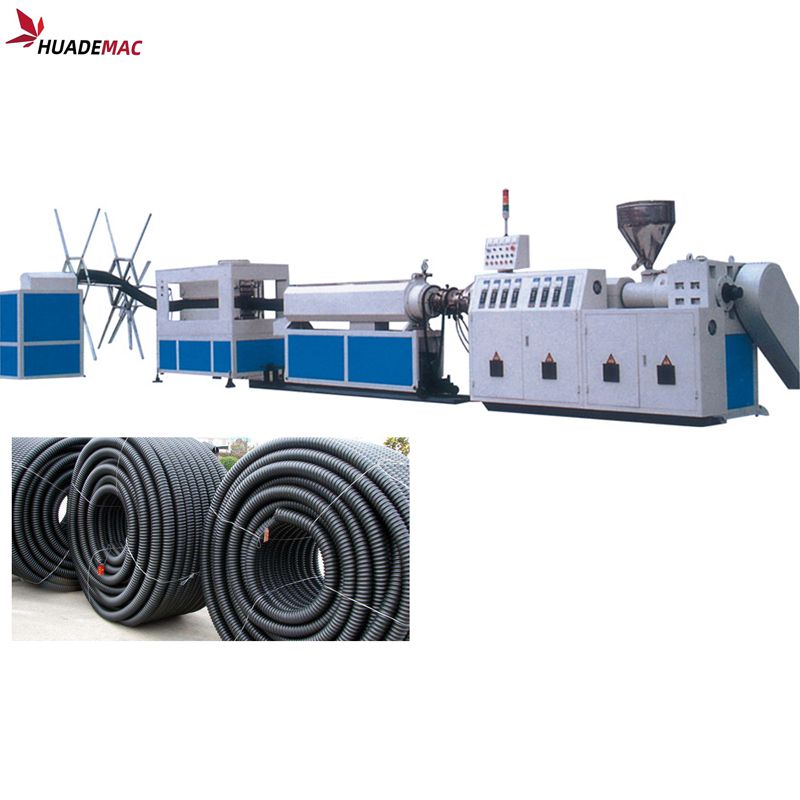

The pe pipe extrusion production line is composed of feeding system, single screw extruder, special mold for pe pipe, sizing, cooling system, traction machine, coupon collector, and control system . The extruder is an important core component of the pipe extrusion line. one , the host pipe processing are used single screw extruder. In the design of single-screw extruder , how to realize high-speed extrusion of high-quality pipe at low processing temperature is a key technology.

In the screw design , the bm structure and the barrier structure are combined , and a special mixing section is added , which not only ensures the plasticization effect of the tube blank , but also the material is in each area on the entire screw , and the melt pressure is lower. , pressure distribution , and strictly control the shear , to obtain a desired material temperature.

In the design of the barrel , using a grooved bush , specially designed liner having a feed structure , the inner bore surface having a plurality of grooves having a slope , in order to ensure pe high speed feeding , the design of a special section in the feed cooling means , in order to achieve a temperature control of the barrel and the feeding region isolation barrel adjacent the high temperature zone. Each section has a barrel heating zones may be temperature controlled , forced air cooling , the extruder has a good linear relationship between yield ( to facilitate synchronization with the pulling speed adjustment ), in order to achieve high-speed extrusion , gearbox is high torque, low noise Gearbox and motor power are matched accordingly.

Cooling and sizing device: The function of the sizing die is to ensure that the high-temperature parison extruded from the die can obtain a fixed geometric shape and size during the vitrification process , and basically eliminate the deformation internal stress and thermal internal stress of the parison in the process. , to obtain products that meet the relevant quality standards , it is the main process device in the plastic extrusion molding process.

Traction device: The traction device is a necessary auxiliary device for the continuous extrusion of plastic pipes . Its function is to provide a certain traction force and traction speed to the pe that has been initially shaped from the machine head , and overcome the friction generated during the cooling and shaping process. , so that the plastic pipes are drawn out from the cooling and shaping device at a uniform speed. And adjusted by adjusting the towing speed pe wall thickness of the tube , to obtain a standard pipe. Practice has proved that the tensile strength of plastic pipes produced without traction force is obviously lower than that with traction force , and the output can be increased when it is produced with a traction device. Towing device requirements. The gripper should be able to meet the needs of supporting the processing of various caliber pipes , and it can adjust the speed steplessly and smoothly within a certain range . During the pulling process , the pulling speed must be stable. Because any irregular changes will form ripples on the surface of the product and affect the quality of the product , the traction clamping force should be moderate and adjustable , and there should be no slipping, jumping and vibration during the traction process , so as to avoid permanent deformation of the pipe.