Manufacturer of pipe technology solutions

- Any Questions?[email protected]

- Get in Tough+86-13601562675

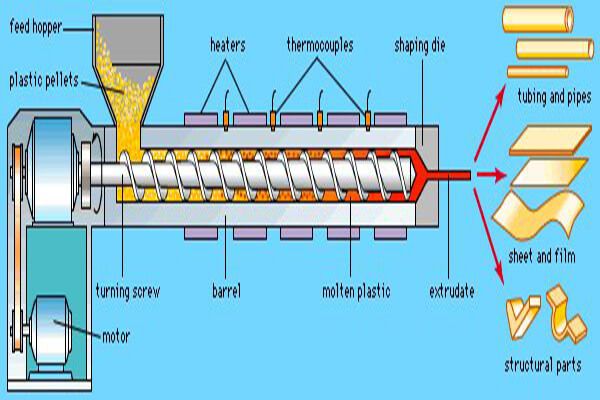

It is understood that in the plastic extrusion molding equipment, plastic extruder is usually called the host, after a hundred years of development, the extruder has been derived from the original single screw twin screw, multi screw, even no screw and other models. Based on its excellent performance, plastic extruder has been widely used, and its future development prospects are also optimistic in the industry.

At present, a variety of plastic extrusion technology has been applied in all aspects of the industry, from the extruder itself screw structure improvement, to the application of new driving motor, as well as the application of various new heating technology, are promoting the development of extrusion technology toward a more efficient energy saving, high yield direction.

With the promotion of the market, the industry presents three characteristics.

First of all, plastic extrusion technology is paying more and more attention to high efficiency and energy saving technology. Energy saving, high efficiency and high yield extruders have become an important direction of technological innovation.

Secondly, the demand for high-performance flexible packaging film in food, beverage, new energy and other industrial fields continues to rise, pushing the multi-layer co-extrusion technology of plastic film to keep innovating.

Finally, China's extrusion technology has begun to increase its research and development efforts in the fields of various auxiliary parts and auxiliary equipment, and the pace of application and expansion of new technologies has been accelerated to promote the rapid improvement of the overall technical level.

In the past two years, China's plastic extruder market has been continuously breakthrough, after long-term development, the international influence of China's plastic extruder industry has been increasing, the ability to cope with trade protectionism has been enhanced, the level of manufacturing technology and overall strength has been further improved, China's extruder industry in the export of foreign trade has gradually appeared favorable conditions.

However, according to import and export data for the first eight months of 2016, China's extruder imports showed a trade deficit of us $13.53 million.

In recent years, the extruder has high speed and high yield, which enables investors to obtain large output and high returns with lower input. The efficiency of plastic extruder is mainly reflected in the aspects of high output, low energy consumption and low manufacturing cost. In terms of functions, the screw extruder is not only used for extrusion and mixing of polymer materials, but also for food, feed, electrode, explosives, building materials, packaging, pulp, ceramics and other fields. In addition, the "one-step extrusion process" which combines mixing granulation with extrusion molding is also worthy of attention. After years of development, China's plastic extruder industry presents three major development trends.